Well Optimization Services

Liquid Level Tracking

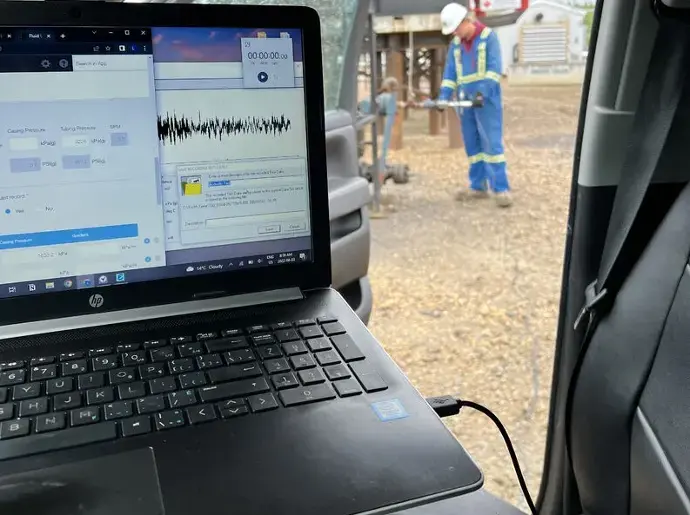

Measuring bottom-hole pressure in producing wells is crucial for optimizing performance. The Acoustic Well Sounder AFDT plays a key role in this process by determining fluid levels and providing accurate bottom-hole pressure readings. Echo Advanced Solutions leverages over 22 years of experience to deliver precise Fluid Level Tracking Surveys. Our field team combines expertise and efficiency, utilizing the latest technologies to operate safely and in compliance with client-specific worksite protocols. Fluid level tracking helps identify the exact volume and behavior of liquids within the well, crucial for effective management and decision-making in well operations.

A foam depression test provides data on pressure and the inflow performance relationship. The purpose of the foam depression test is:

- To measure PBHP (Producing Bottom-Hole Pressure)

- To ensure accurate measurements by depressing any foam prior the monitoring

Using foam depression testing (AFDT - Annular fluid depression testing) and well monitoring, Echo Optimization can help determine the following:

- What is the depth to the liquid level?

- Is the liquid level rising or falling?

- Is the liquid level within a pre-set depth interval?

At a minimum, we should complete at least two shots 15 minutes (or a change in pressure of 300-400kPa) apart. Ideally, we would continue to determine fluid levels until the fluid reaches bottom or a gradient of 8kPa/m or greater for at least two consecutive shots.

Using our Echometer equipment we can determine the percentage of gas in the fluid and therefore calculate an accurate bottom-hole pressure.

Annular Fluid Depression Testing allows you to accurately gauge how much pumpable fluid you have and allows you to calculate accurate bottom-hole pressures.

Acoustic Measurement

At Echo Advanced Solutions, we harness cutting-edge tools such as Echometer Wireless Gas Guns and NR Tec Smart Shots to deliver accurate and timely test results at competitive rates. Utilizing state-of-the-art technology, we expertly measure and enhance well productivity, reservoir performance, and overall well performance. Our precise measurements of annular fluid levels, surface pressures, and pressure transient responses enable detailed analysis. Our well-trained field technicians are committed to providing high-quality data, empowering you to make informed decisions for optimal well performance. This dedication ensures that every client achieves superior results in their well operations.

The following are partial lists of typical questions that can be answered by proper use and interpretation of Echometer measurements:

- Is there liquid above the pump? At what depth is the top of the liquid column?

- Is gas flowing up the annulus? If yes, at what rate?

- What is the casing-head pressure? Is it changing with time?

- What is the percent liquid in the annular fluid column?

- What is the pressure at the perforations?

- What is the percent of the maximum oil rate that is currently being produced?

- What is the maximum rate that could be produced from the well?

- What is the sound speed in the annular gas?

- What is the average gravity of the gas in the annulus?

- Are there any restrictions or anomalies in the annulus above the liquid level?

Regular fluid level shots are a cost-effective way to increase production and save money on costly equipment repairs.

There is no replacement for experience. Many fluid level traces are easy to interpret but there are also many mistakes that can be made. Basing decisions on false data can result in large amounts of money wasted. Using experts significantly reduces errors.

Lots of noise downhole, gas motors, compressors, low or negative pressure make it challenging to shoot a fluid level. We may have to shut down the pumping well, gas motors or compressors but it is extremely rare for our technicians not to pick up a fluid level.

Dynamometer Measurement

Echo Advanced Solutions utilizes advanced dynamometers to diagnose a variety of downhole issues, including parted rods, intermediate rod stress, pump intake pressures, unanchored tubing, and leaking production strings. Our team excels in analyzing pump efficiencies and enhancing mechanical designs. We provide precise Dynamometer measurements and detailed analysis reports, or direct data delivery for client-led analysis. Echo with help of high qualified team of engineers at NR Tec are your trusted partner for comprehensive Dynamometer assessments and optimization of downhole conditions.

Dynamometer measurements provide diagnostics to analyze the optimization of the pumping system including well pumping efficiency, production, rod and pump life, gearbox failures, and pumping equipment design. Echo provides the option to have our engineers analyze the data or to provide the raw dynamometer data that you can create the analysis on your own.

Here are some of the questions we can answer with our Dynamometer Measurement Services:

- Is the well pumped off?

- What is the percent pump fillage?

- Are the traveling and/or standing valves leaking?

- What is the pump displacement in barrels per day?

- What is the effective pump plunger travel?

- What is the current pumping speed? What is the fluid load on the pump?

- Are the maximum and minimum polished rod loads within the capacity of the pumping unit and the rods?

- What is the polished rod horsepower?

- Is the maximum torque less than the gearbox specification?

- Is the unit properly balanced?

- What movement of the counterweights is required in order to balance the unit?

- What is the weight of the rods in the fluid?

- Does the pumping system require a detailed analysis and/or redesign?

Dynamometers can help diagnose downhole issues such as parted rods. We can also analyze pump efficiencies and help improve mechanical designs.

- Is the well pumped off?

- What is the percentage of pump fillage?

- Are the travelling and/or standing valves leaking?

- What is the effective pump plunger travel?

- Is the maximum torque less than the gearbox specifications?

- Is the unit properly balanced?

- …and more.

Pressure Transient Survey

Echo Advanced Solutions excels in conducting comprehensive Pressure Transient Analysis (PTA) with over 22 years of proven expertise serving the Oil & Gas sector across Alberta. We leverage the latest technologies, hardware, and software to deliver crucial measurements and performance analyses for enhancing operational profitability. Our capabilities include measuring well deliverability, assessing reservoir pressures and temperatures, evaluating formation damage, and analyzing fluid samples for PVT analysis. We also assess completion efficiency, reservoir dimensions, and communication between wells, providing insights into reservoir heterogeneities and key performance parameters.

Pressure Transient Analysis provides a primary source of dynamic reservoir data. These performance tests should be completed at multiple stages of drilling, completion, and production. Pressure Transient Analysis uses changes in pressure performance to measure reservoir data such as flow capacity, average reservoir pressure in the drainage area, reservoir size, boundary and fault locations, wellbore damage and stimulation, and well deliverability. Echo Optimization works with a very experienced team of engineers to supply top-quality reporting and provide accurate results to questions such as:

- What is a good estimate of reservoir pressure?

- What is the flowing bottom-hole pressure?

- What is the pressure buildup rate?

- Is there annular afterflow of liquid/gas when the well is shut-in?

- Is there any wellbore damage?

- Is the well fractured?

- Does the well require a detailed pressure transient analysis?

Reservoir Performance

At Echo Advanced Solutions, we understand that strategic reservoir performance analysis is crucial to enhancing both operational longevity and investment returns. Our dedicated teams utilize cutting-edge technology to deliver in-depth analysis, unlocking reservoir potential and streamlining financial outcomes. Our services not only optimize resource recovery but also significantly boost profitability by providing targeted insights. Working across Alberta, our collaborative efforts between expert field technicians and top engineers ensure that every project delivers exceptional value.

Echo Advanced Solutions partners with an expert and competent team of NR Tec engineers to support our excellent data collection services with top-notch analysis and reporting by experienced engineers.

Together we provide:

- Annular Fluid Depression Test: includes calculations to determine an accurate producing pressure on a well using fluid level data and measured casing pressures.

- Inflow Performance Relationship: includes a graph and tabular display with calculations of maximum production potential.

- Static Pressure Calculations (SSBHP): includes surface pressure measurements, calculated subsurface pressure, gas & liquid column lengths and gradients.

- Acoustic Pressure Survey (BU Test): includes calculated subsurface pressures, gas & liquid column lengths and gradients, and diagnostic plots (log-log, bottom hole pressure, casing pressure, and liquid level). The report also includes a summary of the entire test.

- Pressure Transient Analysis: includes Flow and buildup analyses (acoustic/surface/gauge data) using Fekete F.A.S.T. analysis software. Drill Stem Test analysis, injection/falloff tests analysis, reservoir limit test, interference test analysis.

We provide a data sheet that you can fill in to supply with us all the information we require.

Yes, we do. Connect with our team at 1-403-895-0373 or fill out our contact form to access our library of sample reports.

- Annular Fluid Depression Test

- Inflow Performance Relationship

- Static Pressure Calculations (SSBHP)

- Acoustic Pressure Survey (BU Test)

- Pressure Transient Analysis

AER & Engineer Reporting

Echo stands out with its highly specialized teams that utilize cutting-edge technologies to provide crucial measurements and performance analyses for enhancing operational profitability. We employ industry-leading tools like the Echometer Model E Well Analyzer and NR Tec Smart Shot, along with NR Tec Surface to Sandface Loggers, ensuring accurate and timely testing results at competitive rates. Our certified and safety-committed field technicians across Alberta, combined with our partnership with NR Tec, deliver unparalleled engineering expertise and top-quality optimization services

Echo specializes in field operations. Our expert team is experienced in all aspects of surface casing vent testing and we provide quality reporting at no extra cost. We can produce PAS file validation and submissions from a single shot bottom-hole pressure on static wells or we can complete AWS gradients on producing wells. We work closely with an amazing group of NR Tec engineers to provide all required engineering.

Satisfy AER reporting requirements with:

- Surface Casing Vent Testing

- PAS file validation and submission

Yes, we do. After calculating a bottom hole pressure we can create and if required submit the PAS files to the AER.

On static wells, we can use just a single fluid level shot along with an accurate pressure to calculate a bottom hole pressure. On producing wells we can perform an AWS (acoustic well sounder) buildup until the fluid in the annulus has stabilized and then calculated a bottom-hole pressure.

Website may use cookies to personalize and facilitate maximum navigation of the User by this site. The User may configure his / her browser to notify and reject the installation of the cookies sent by us.

Mechanical Performance

Echo Advanced Solutions, in partnership with NR Tec, offers top-tier Mechanical Performance Analysis at competitive rates. Our services, enhanced by expert engineering support from NR Tec, include Dynamometer Analysis with integrated Pumping System Design. We focus on sizing and balancing pumping units for peak performance, ensuring the most comprehensive and detailed Mechanical Performance analysis and reporting. This powerful collaboration between Echo Optimization and NR Tec ensures high-quality, inclusive results for our clients.

Top

THE ECHO DIFFERENCE

The Echo Difference stands out through our comprehensive suite of services designed to enhance the operational efficiency of the oil and gas industry. With over two decades of expertise, Echo Advanced Solutions brings you top-tier well optimization, meticulous pipeline crossing representation, and cost-effective screw pile installation. Our services utilize cutting-edge technology and deep industry knowledge, ensuring every project benefits from optimized performance, safety, and cost savings. Let our experienced team, including the expert "Screw Crew," provide the support and solutions needed to maximize your operations efficiently and sustainably. Trust Echo to make a real difference in your projects.